How Does A Furnace Work?

What is a Furnace & How Does it Work?

A furnace is the home appliance that is responsible for evenly distributing heat throughout a home. It accomplishes this by circulating hot air through the ventilation system. The furnace serves the same function as a boiler which heats water and then circulates that through plumbing that warms radiators throughout a home. The difference is a central furnace introduces heat via combustion of natural gases or through electrical resistance which heats the surrounding air and then gets blown throughout a home or business.

Table Of Contents

1. What is a Furnace & How Does it Work?

2. Parts of a Furnace

3. How Does a Furnace Work?

4. Different Fuel Types for Furnaces

a. Electric vs Gas Furnaces

5. Different Types of Furnaces

6. Different Furnace Fan Types

7. How to Determine the Right Furnace Size

8. How is Furnace Efficiency Measured?

9. Which Furnace Should You Get?

10. Furnace Safety & Maintenance

11. Replacing Your Furnace

12. Furnace FAQs

Parts of a Furnace

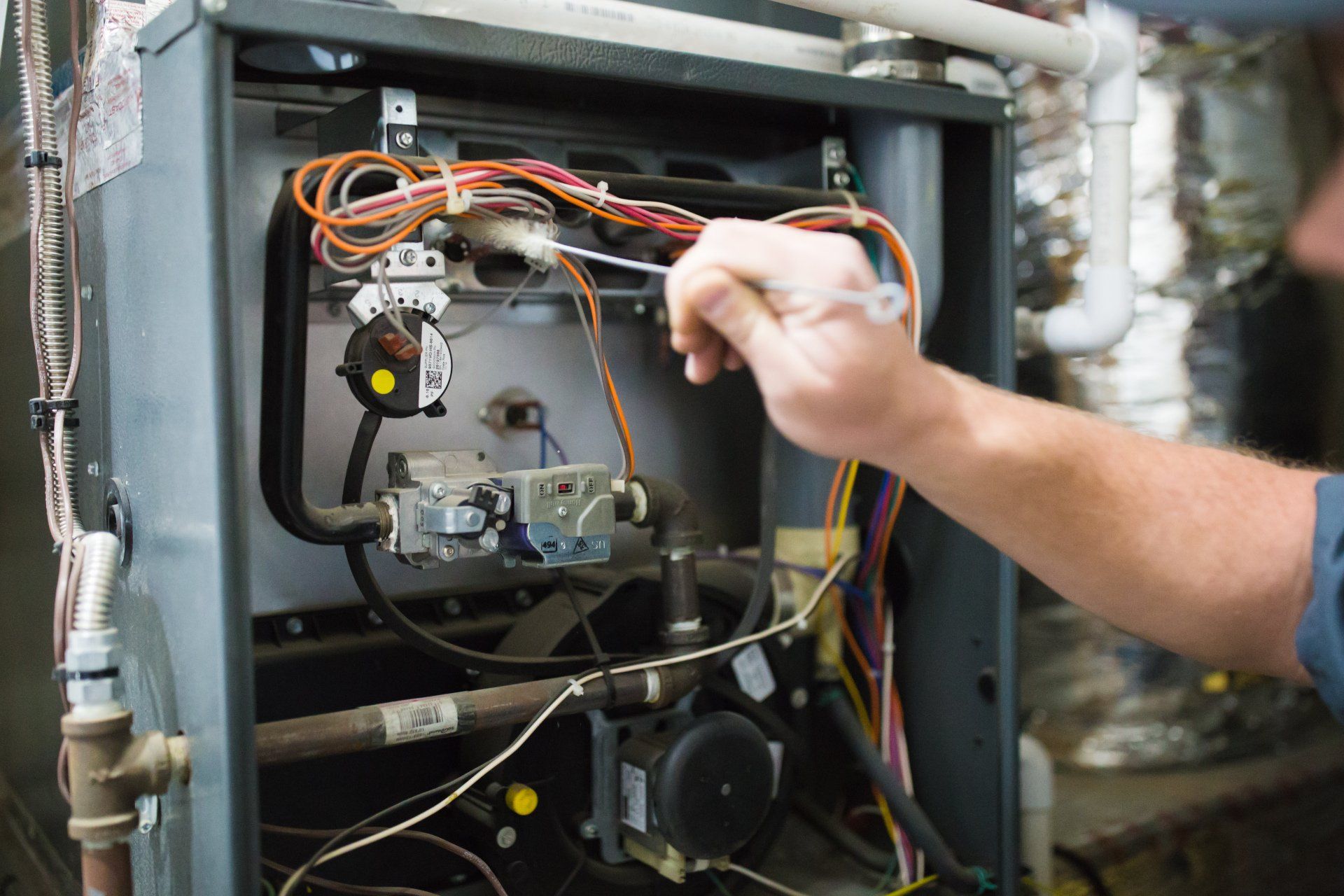

A furnace combines the function of 6 different elements to heat a home. If any of these elements fail, the furnace system will lose efficiency and could potentially stop working.

- Thermostat: The thermostat is responsible for activating the furnace when the temperature drops below a set level.

- Control Board: the electrical element that regulates the signals that allow the thermostat, gas valve, and blower fan to work together for furnace operation.

- Gas Valve: The gas valve is responsible for regulating the release of fuel to the pilot light.

- Burners: The burners are the metal tubes and outlet in which the combustible fuel travels through before reaching the gas valve and pilot light.

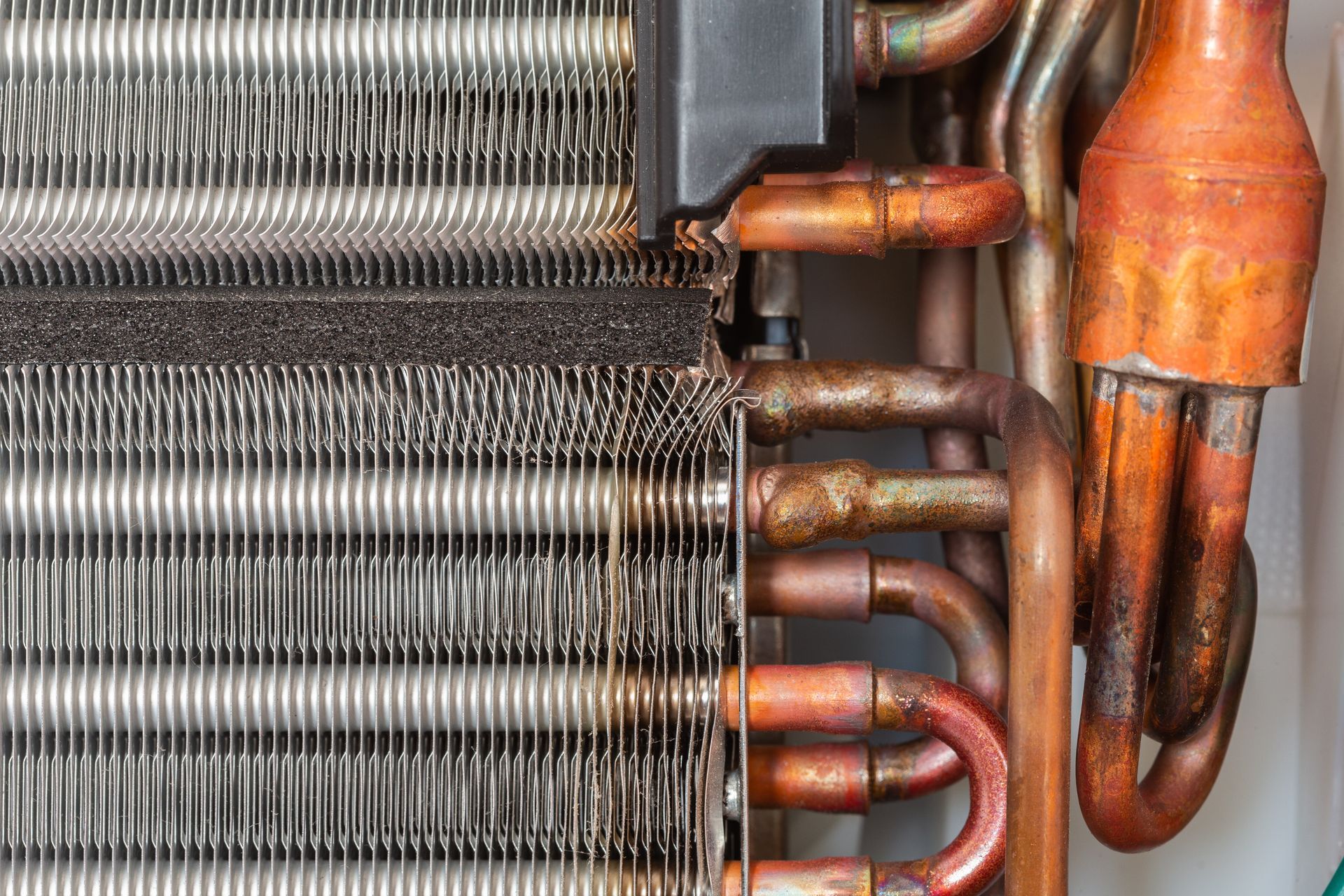

- Heat Exchanger: This element is made up of thin-walled metal tubes that allow the combustion to warm air as it passes through the furnace. It is designed to prevent actual flames from the burners to pass through the system.

- Blower Fan: The fan and motor pushes hot air from the heating elements and directs it through the vents to reach the rest of the property.

- Air Ducts: Ductwork connects the furnace to each of the rooms and is responsible for taking hot air from the furnace to their destinations.

- Flame Detector: This element ensures that the pilot light is activated and is designed to shut off gas flow if no flame is present to prevent a gas leak.

- Flue: This vents out any combustion gas waste to prevent a build up of carbon dioxide / monoxide buildup which can have deadly repercussions if allowed to build up in a home.

- Air filter: A thin membrane that is responsible for removing particulates from the air being blown throughout a home.

How Does a Furnace Work?

A furnace operates by integrating all the components and ensuring that each element works properly in conjunction with the other components.

The thermostat allows a user to establish a base level temperature that needs to be maintained. When the temperature drops below the designated temperature level, a signal is sent from the thermostat to the control board to activate different components like the gas valve and blower fan. The control board sends signals to the gas valves to release more fuel. Opening the gas valves allows more fuel to be ignited by the pilot light, which then heats the air that passes over the heat exchanger. This creates additional heat within the furnace, which is then pushed through the ductwork by the blower fan. The blower fan helps push warm air out through the air filter while also pulling in cooler air to be heated. This system repeats this process until the heat level within a home or business reaches the desired temperature established by the thermostat. Any excess combustible gasses that are created or wasted by the system are discharged by the flue, so they do not pose a threat to the inhabitants of the property.

Different Fuel Types for Furnaces

Furnaces rely on a combustion source that can vary with each furnace. The most common fuel types are:

- Propane furnaces: Propane is just one of several natural gas sources used to fuel a furnace. This fuel source is usually contained in tanks on a property that need to be refilled. The fuel tanks come in different sizes but are commonly found outside of a home or business and are not connected to a city’s infrastructure.

- Natural Gas Furnaces: Natural gas is another gas source used to fuel combustion. This source is usually connected to gas lines that are connected to a gas main that are connected to a city’s infrastructure and do not need to be refilled like propane.

- Oil Furnaces: This natural fuel source is usually pulled from an oil tank using a fuel pump because it comes in liquid form. This liquid oil is then compressed and dispersed in a fine mist which is sprayed into a combustion chamber connected to a burner. This heats the combustion chamber which then allows heat to be distributed.

- Electrical Furnaces: This furnace type does not require a fuel source for combustion as it relies on the heat generated through electrical resistance to heat up the surrounding air before being distributed by the blower.

Electric vs Gas Furnaces

The most common dispute between fuel sources is choosing either a gas or electric furnace. Each fuel source has their distinct benefits and downfalls. Determining if a gas vs electric heater is right for you requires an individual to evaluate their specific needs. Gas burning furnaces tend to more cost effective in operation because gas tends to be cheaper than electricity, but they also require a city gas main connection to function. Gas heaters are also capable of producing more heat in a shorter time frame which means that the same sized space will be heated faster by a gas fueled heater. Natural gas fueled furnaces tend to last between 15 – 20 years when maintained properly. That being said, gas heaters generally require more maintenance and upkeep which can add additional costs. They also introduce hazards like gas leaks and the potential release of carbon emissions.

Electric heaters, on the other hand, last longer with less maintenance. A typical electric heater can last between 20 – 30 years with much less upkeep. They typically cost more to operate due to electricity costing more. That said, they can have increased efficiency because newer units come with smart controls that allow heat to be dispersed where it needs to be. They are quiet and do not release harmful emissions.

Different Types of Furnaces

Most furnaces are categorized into one of four categories:

- Natural Draft: These furnace types are usually dated models that don’t use a blower fan to distribute air. Their efficiencies are some of the lowest at 65%- 70%, as there is nothing to propel heated air through the system.

- Forced Air: Newer forced air systems utilize a blower fan to draw and push air through the system. These are more common and have a slightly higher efficiency level.

- Induced Air: Induced air models are similar to forced air units but with an additional fan that draws air into the unit to help supply the furnace with cool air to warm while also expelling wasted gas. This relieves pressure on the blower fan, so it is not responsible for the draw and push of air flow which increases efficiencies.

- Condensing: Condensing furnaces are highly efficient furnace units that use a secondary heat exchanger to draw additional heat from exhaust gasses before they are expelled via the flue. This condensed heat is added to the heat that is already being dispersed which can reach efficiency levels of 98%.

Different Furnace Fan Types

The other way in which furnaces are differentiated are the type of fan that is being used:

- Single Stage: A single stage furnace has 2 modes of operation: ON and OFF. This typically means that efficiencies are not being maximized because the system is always operating at maximum level. This can cause rooms to reach their desired temperature quickly but also results in the system turning off more frequently. This is called cycling and is not efficient and also increases the wear and tear on a unit.

- Two Stage: A two stage furnace is slightly more efficient than a single stage unit because it introduces a reduced speed option. This allows an area to be warmed without cycling on and off frequently.

- Modulating: The modulating furnace is the most efficient because it is capable of adjust output depending on the needs of a home. This means that it only works as hard as necessary without cycling which saves energy. These models are more expensive but save money in the long run.

How to Determine the Right Furnace Size

Determining the proper size for a furnace requires completing a load calculation. This equation is typically the only way to properly and accurately determine the size of a furnace to achieve optimal efficiency and production. It determines the potential heat gain and loss throughout a building which assists in determining the proper size of a furnace unit. The load calculation accounts for the square footage of space, number of doors and windows, the thickness of walls, the amount and effectiveness of insulation, and even the number of occupants to determine the proper size of a furnace unit. HVAC contractors can input each of these variables into a calculation on a computer which will return the optimal furnace size for your home or business.

How is Furnace Efficiency Measured?

How efficient your furnace is depends largely on its annual fuel utilization efficiency (AFUE). This metric indicates how much fuel is being effectively being used for heat and how much is being lost due to combustion waste and heat dispersal when passing through ductwork. If a unit has a 90% AFUE rating, this means that 90% of the fuel is being used for heat, while 10% of the fuel is being wasted. A 90% rating qualifies a unit as high efficiency while anything less is mid-grade (80% - 90%) and low grade (50% - 80%). Older units usually fall into the low efficiency rating which is why it is sometimes more cost effective to replace an older unit with a higher efficiency model. It is important to note that the rating can decline if a furnace isn’t maintained properly. Heat leakage, dirty components, damaged parts, and clogged filters can all result in a drastic decline in efficiencies which makes maintenance and upkeep critical to maintaining a high AFUE rating.

Which Furnace Should You Get?

The type of furnace someone should get largely depends on an individual’s needs and budget in addition to variables like local climate, fuel costs, square footage, and insulation values. It is generally recommended that a furnace with the highest efficiency rating within a budget is selected to reduce the lifetime costs of operation. This generally means that most people should opt for a new furnace unit with at least a 2-stage fan paired with induced air or condensed air capabilities. The fuel type can fluctuate but in colder climates, gas fueled units are more likely to be needed because electric units draw too much power to heat extremely cold climates. Determining make and model of a unit should be done with the help of an HVAC professional so they can help guide a decision with the best information available. They will use their knowledge and the load calculation to determine the best size, make, and model for the desired functionality of your furnace unit.

Furnace Safety & Maintenance

Regardless of which type of furnace unit an individual decides on, regular maintenance and upkeep is recommended to keep the furnace unit operating at maximum efficiency. Regular maintenance will ensure that all of the furnace components are in good shape and that the furnace is operating as expected. Checkup tasks like replacing filters and inspecting the pilot light to ensure it is lit will ensure that your furnace isn’t clogged in a way that forces other components to work harder than necessary. Regular maintenance will also ensure that the furnace is operating safely and not producing excess amounts of hazardous gasses like carbon monoxide or CO2.

Replacing Your Furnace

If you are deciding to repair or replace your furnace, it is important to speak with a qualified HVAC system professional to help determine the best route of action. Sometimes a replacement makes more sense if an existing unit is near the end of its lifespan and requires continuous repairs. Another consideration for replacement is if an outdated unit has such poor energy efficiency that a new furnace unit would offset the initial cost of replacement in the long term by increasing energy efficiency. Regardless, speaking to a Greener Solutions Home Services HVAC expert will provide the necessary guidance as well as all of the potential options on how to move forward.