What is an AC Compressor?

An air conditioner’s air compressor is a central component to the operation of every HVAC system. If an HVAC system had biological parts, the compressor would function a lot like a heart. AC compressors keeps refrigerant pumping through the air conditioning system by compressing the refrigerant in its gaseous form right before it reaches the condenser. Compressing the refrigerant superheats the gas which prepares the refrigerant for the next necessary phase change required for heat transfer. Once the refrigerant is pressurized, it gets released into the condenser where the refrigerant can transfer the heat outside and cool back into liquid form to start the process over again. Without this critical component, air conditioners would not be able to provide cool air.

How Does the Air Conditioner Compressor Work?

In order to understand the role of the HVAC compressor, it helps to understand how air conditioner’s function. AC units rely on pressure and the evaporation and condensation process to effectively transfer heat and every AC unit relies on a refrigerant to help with this process. The air conditioner compressor is a critical element that provides the temperature and pressure needed to sustain the refrigeration process and can be found outside the home near the condensing unit. Before refrigerants reach the compressor, the refrigerant is in a super cooled liquid form. This liquid refrigerant passes through evaporator coils where it is exposed to the ambient indoor temperatures inside a home. Warm air passes over these evaporator coils causing the heat from a home to warm the super cooled refrigerant.

Like any liquid exposed to heat, the super cooled refrigerant evaporates inside these coils. This transfer of heat results in the warm air that passed over the evaporator coils being cooled and returned into the house. When the refrigerant becomes warmed up and evaporates is when the compressor comes into play. The compressor contains the gaseous refrigerant from the evaporator coils that has collected all that indoor heat and pressurizes the gas. This is necessary to superheat the gas as gas under high pressure increases in temperature as the ambient heat is compacted into a smaller space. This is accomplished using a motor that rotates a piston inside of a cylinder. The rotation of the piston both draws in refrigerant and contains it in a way that the rotation of the piston pressurizes the gas. The same mechanism is used in car engines to draw in and compress fuel before it is ignited and released.

Then the pressurized, super-heated gas gets released into the AC condenser where the gas will pass through the condenser coils. When this occurs, the superhot gas cools rapidly inside the AC unit, which causes the gas to condensate back into its liquid form before being pushed back through the air conditioner to start the process over again.

Types of AC Compressors

AC compressors all operate using the same principle of producing significant amounts of pressure to superheat gas, but there are several types of compressors that exists in today’s market. Understanding the differences between the different types of AC compressors.

Reciprocating Air Conditioner Compressor

Reciprocating compressors is the industry standard and most common AC compressor. This functions exactly like a car motor using a motor and crankshaft to rotate up to 8 pistons inside a block with airtight cylinders. The up and down movement of the pistons create vacuums that draw in gaseous refrigerant into the chamber before compressing that gas to superheat it. Once the refrigerant is pressurized and hot, it gets released into the condenser unit.

Scroll Air Conditioning Compressor

Scroll compressors are the newest compressor to hit the market and its efficiency and reliability are making it a popular addition. This type of compressor has the least amount of mechanical complexity and uses the fewest moving parts. The way this compressor functions is by using 2 spiral scrolls that are attached to motors and are laid inside each other to create a chamber. As the scrolls rotate against each other, they trap refrigerant which moves towards the center of the scroll to get pressurized. The rotating movement of this compressor makes it so there is a constant and consistent flow of pressurized refrigerant.

Screw Air Conditioner Compressor

Screw compressors are typically used in commercial building with lots of space. These types are extremely reliable and efficient but wouldn’t normally make sense in residential homes. The way this compressor works is by rotating 2 intermeshing screws that draws in the refrigerant and then pressurizes it as the turning rotors move the refrigerant down the chamber.

Rotary Air Conditioning Compressor

Rotary air conditioner compressors are generally used when noise is a consideration. These units are small, quiet, and produce far less movement than the other compressor types. This mechanism relies on an offset rolling piston that spins inside a slightly bigger cylindrical housing to create a constantly moving chamber. This mechanism also contains a sliding vane that moves in tandem against the rolling piston to trap the refrigerant. As the motor spins, the chamber moves around the interior rolling piston to draw in refrigerant. That refrigerant will be compressed against a vane before getting released.

Centrifugal Air Conditioning Compressor

Centrifugal compressors are the most expensive and complex compressor type and are only found in large scale commercial projects. Centrifugal compressors suck refrigerant into the impeller which spins fast enough for the centrifugal force to pressurize the refrigerant at the edge of the impeller.

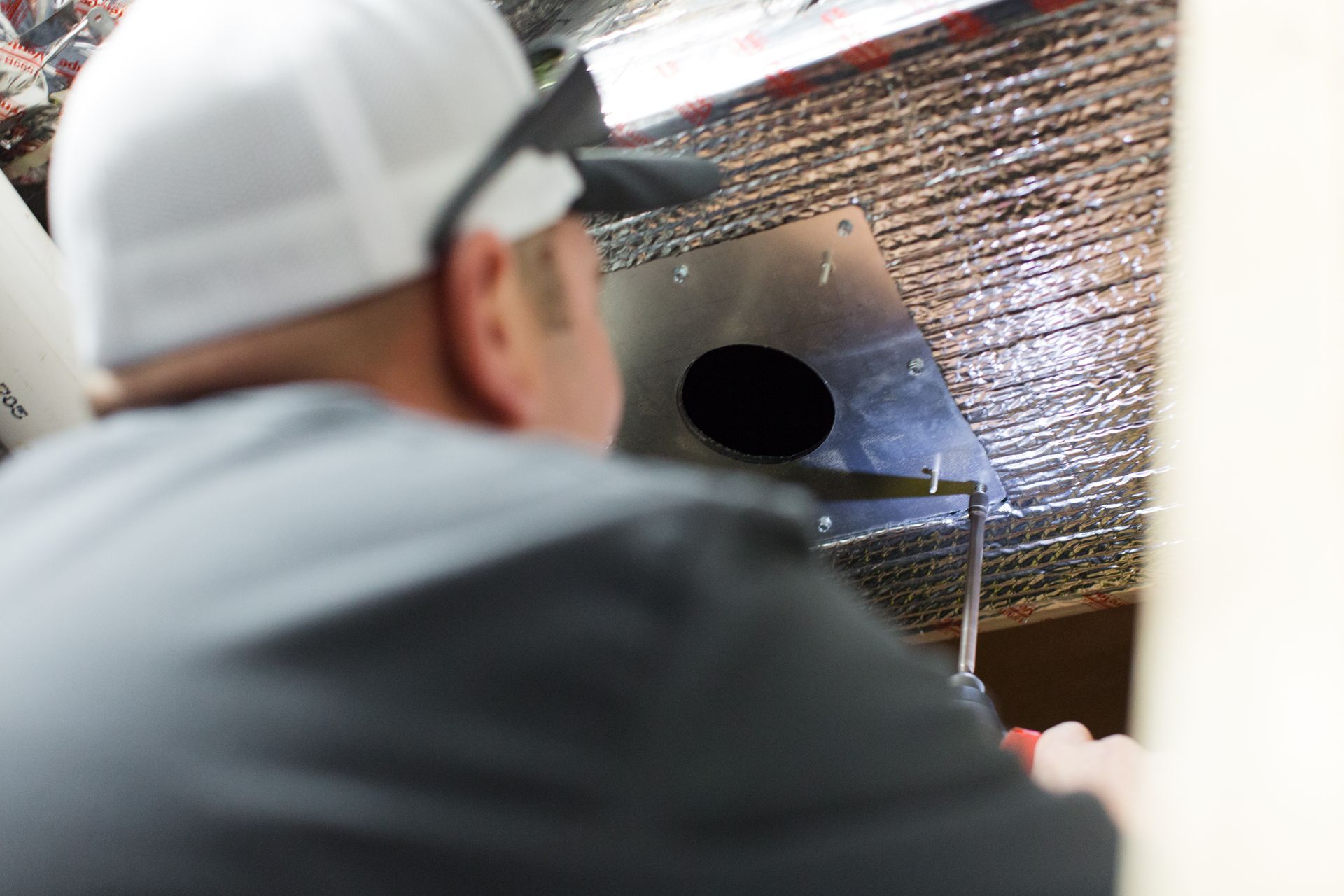

How to Maintain an AC Compressor

Just like anything with moving parts and a motor, the compressor needs regular monitoring to ensure optimal operation. This typically involves checking on performance and oil levels to ensure everything is functioning properly. HVAC compressor inspection is generally done as part of regular HVAC maintenance services. If a problem is discovered, the compressor will likely need to be replaced. However, if the AC is inspected and maintained regularly, the compressor should last for 10 – 15 years without problems. Regular maintenance should be done on AC units at least once a year right before summer heat rolls in. In addition to regular annual maintenance, the other thing homeowners can do to help prolong the life of their AC compressor is keeping the outdoor unit clean and free of debris and leaves.

Signs That Something is Wrong with the AC Compressor

The compressor is a complex mechanism with lots of moving parts. This means that breakdowns are completely possible if something is causing a problem. The primary signs something is wrong with an AC compressor are:

- Noises: All compressors use a motor to spin the internal components of a compressor. If something becomes damaged or knocked loose inside the compressor, this movement can result in banging, clicking, clanking, or some other disruptive and repetitive noise. Ticking is another sound that indicates an electrical malfunction and hissing or bubbling is indicative of a refrigerant leak which can lead to other serious problems.

- Not Cooling: Compressors drive the pressure of the refrigerant that keeps it flowing through the system. If there is a compressor leak, the AC unit won’t be able to pressurize the refrigerant vapor which will result in air not being cooled and the compressor being overworked.

- Hard Starting: This refers to when the compressor is unable to power the motor enough to overcome the pressure inside the unit. This can be the result of a failing motor or lack of lubrication. Regardless of the reason, this puts unnecessary wear and tear on the unit and drains a higher amount of power.

Common Problems with Air Conditioner Compressors

The different signs of compressor problems indicate that something is wrong with the “heart” of the AC unit. However, identifying the problem is the first step to getting an AC unit fixed.

Electrical Issues

Electrical issues can present themselves in any connection and are typically the more costly repairs needed when it comes to fixing a compressor. This is because electrical issues can often result in permanent damage that require that the compressor be replaced altogether and sometimes even the failure of other components as well.

Improperly Sized Suction Line

Suction lines carry refrigerant and lines that are too small or too big impact the flow of refrigerant into the compressor. When these refrigerant lines are too small, they will restrict the flow of refrigerant into the compressor. Suction lines that are too big can result in refrigerant leaks. When this occurs, it is usually the result of an unqualified HVAC technician who did a poor installation job.

Blocked Suction Lines

Similar to restricted suction lines, blocked suction lines will prevent the flow of refrigerant altogether. When this happens, the AC unit can no longer cool and the rest of the AC unit will attempt to operate until some other component fails. This will ultimately result in expensive repairs of several mechanical components.

Too Much Refrigerant

Another problem that is the result of an unqualified HVAC technician is having too much refrigerant inside your AC unit. This makes it difficult for the refrigerant to phase change from liquid to gas without enough space for evaporation to occur. When this happens, liquid refrigerant can end up in the compressor which can cause damages since liquids can’t be compressed like vapors can.

Too Little Refrigerant

Too little refrigerant could be indicative of a compressor or coil leak. Whenever this occurs, the compressor must work extra hard to effectively cool a space. If the compressor has a leak the units will need to be repaired or replaced to prevent further refrigerant discharge.

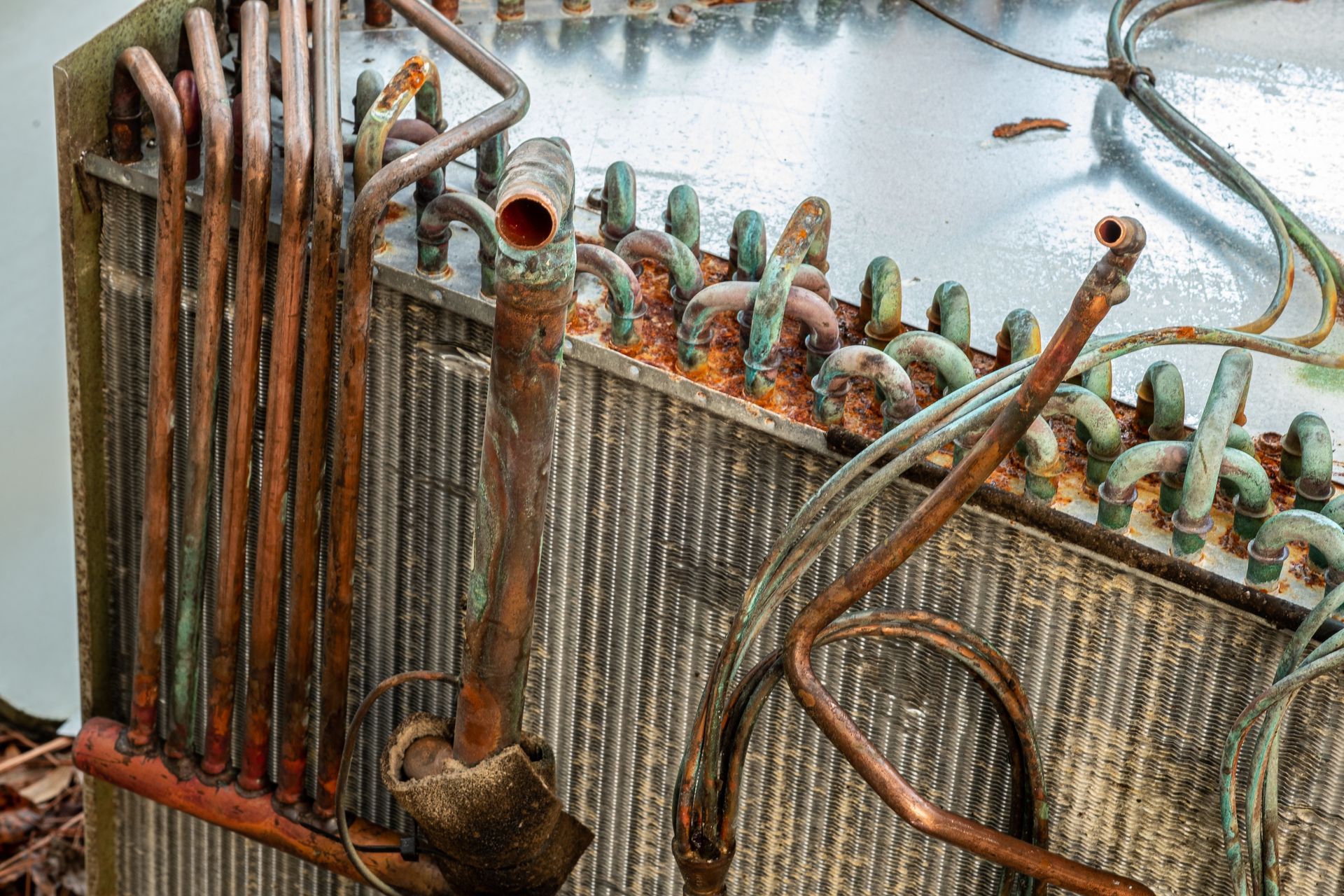

Dirty Coils

Evaporator and condenser coils are where the refrigerant collects and expels the heat. If these coils get dirty, the heat won’t be able to transfer which impacts the AC unit’s ability to cool. If the cooling ability of the AC unit declines, the compressor will have to work harder to do its job. If this happens for a long enough period, the compressor will eventually overheat and fail.

Poor Lubrication

Like anything with a motor, compressors do need to be well oiled to operate efficiently. Regular lubrication shouldn’t be needed because the lubrication inside of a compressor is contained. However, if there is an oil leak, then oil levels might need to be filled up during regular AC maintenance service.

Contact GS Home Services if You Need an AC Compressor Inspection

The best way to ensure optimal AC compressor operation is to get your AC unit regularly serviced by qualified and experienced HVAC professionals. GS Home Services provides regular AC maintenance contracts that provide annual checkups and AC compressor inspections. We will inspect your unit’s oil and refrigerant levels and top off anything we see is running low. Call today to talk with one of our AC experts!

AC Compressor FAQs

-

What does an AC compressor do?

An air conditioner compressor works as the engine of an air conditioner. It pressurizes the refrigerant, so it gets pumped through the AC coils. Without it, the ability to cool the air would be impossible.

-

What happens if AC compressor goes out?

An air conditioner compressor can fail due to internal damage, electrical issues, or excessive wear and tear. When this happens, the compressor will need to be inspected to determine if the unit can be repaired or if it needs to be replaced.

-

What are the symptoms of a bad AC compressor?

The primary indicators that an AC compressor is having issues are not cooling properly, making noise, and hard starting. If an AC unit is showing any of these signs, the AC compressor could be responsible.

Recent Posts

-

Our Services

ButtonSee All Our Services

-

About

ButtonLearn More about

Greener Solutions

-

Contact Us

ButtonImmediate Service

Emergency Services

Live Support

Have an HVAC emergency? Call for immediate service. Available 24/7